Project Description

BURGOS “LAMINATED” CHOCKY BARS 700 HB / 63 HRC

Burgos laminated 700 HB / 63 HRc Chocky Bars are easy to use

Burgos Chocky Bars are easy to use and install. Used for a variety of wear protection on buckets, excavators, dragline machines or for lining chutes and rock box edges, available in a wide range of sizes. They can be bent, cut and formed onto inside or outside contoured surfaces to provide an extra level of protection for wear and impact applications.

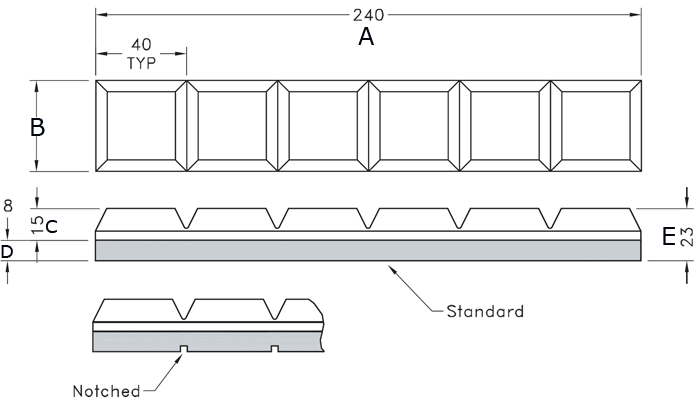

Burgos Chocky Bars have two types: standard type and notched. The standard length is 240mm, the standard thickness is 23mm, and the width could be from 25mm to 150mm. We can supply special type according to customers drawing.

| Part NO. | Notched | Size(mm) | A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | Unit Weight(kgs) |

|---|---|---|---|---|---|---|---|---|

| CB25 | No | 240x25x23 | 240 | 25 | 15 | 8 | 23 | 0.9 |

| CB25N | Yes | 240x25x23 | 240 | 25 | 15 | 8 | 23 | 0.9 |

| CB40 | No | 240x40x23 | 240 | 40 | 15 | 8 | 23 | 1.5 |

| CB40N | Yes | 240x40x23 | 240 | 40 | 15 | 8 | 23 | 1.5 |

| CB50 | No | 240x50x23 | 240 | 50 | 15 | 8 | 23 | 1.9 |

| CB50N | Yes | 240x50x23 | 240 | 50 | 15 | 8 | 23 | 1.9 |

| CB65 | No | 240x65x23 | 240 | 65 | 15 | 8 | 23 | 2.5 |

| CB65N | Yes | 240x65x23 | 240 | 65 | 15 | 8 | 23 | 2.5 |

| CB80 | No | 240x80x23 | 240 | 80 | 15 | 8 | 23 | 3.2 |

| CB80N | Yes | 240x80x23 | 240 | 80 | 15 | 8 | 23 | 3.2 |

| CB90 | No | 240x90x23 | 240 | 90 | 15 | 8 | 23 | 3.5 |

| CB90N | Yes | 240x90x23 | 240 | 90 | 15 | 8 | 23 | 3.5 |

| CB100 | No | 240x100x23 | 240 | 100 | 15 | 8 | 23 | 3.9 |

| CB100N | Yes | 240x100x23 | 240 | 100 | 15 | 8 | 23 | 3.9 |

| CB130 | No | 240x130x23 | 240 | 130 | 15 | 8 | 23 | 5.2 |

| CB130N | Yes | 240x130x23 | 240 | 130 | 15 | 8 | 23 | 5.2 |

| CB150 | No | 240x150x23 | 240 | 150 | 15 | 8 | 23 | 7.3 |

| CB150N | Yes | 240x150x23 | 240 | 150 | 15 | 8 | 23 | 7.3 |

Features:

- metallurgically bonded martensitic white iron bonded to a weldable, impact resistant backing plate;

- 700 HB Chocky Bars offering superior wear and impact resistance when compared to Chrome-carbide clad plate and hard facing;

- Chocky Bars are manufactured with notch on the mild steel backing plate to be easily cut and shaped to fit over contoured surfaces.

Benefits:

- ease of use and installation, can be formed in bends and curved surfaces;

- significant increase in lifespan when compared to AR plates, Chrome-carbide plates and hard facing;

- less downtime and maintenance on worn parts;

- very cost effective due to extended lifespan compared to hard facing and overlays.

Applications:

- bucket wear strips;

- replaces hard facing for augers, directional drill heads, foundation drilling, raise bore drilling;

- fan blade liners;

- pugmill paddles, tip and scrapers;

- recycling industry;

- road planer skids and pick protectors;

- replaces hard facing for pump housings and impellors.