Project Description

BURGOS “LAMINATED” WEAR DONUTS 700 HB / 63 HRC

Burgos laminated 700 HB / 63 HRc Wear Donuts are easy to use

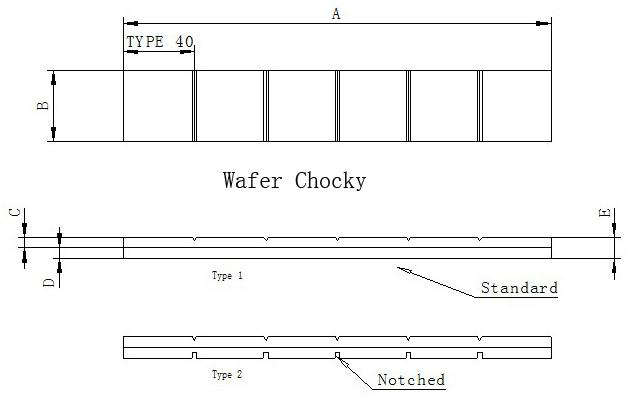

Burgos Wafer Chocky is so thin to be ease of use and installation, while Rockbox Liner is heavy to provide the greatest impact and wear protection.

| Part NO. | Type | A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | Unit Weight(kgs) |

|---|---|---|---|---|---|---|---|

| WC11 | 1 | 240 | 25 | 6 | 6 | 12 | 0.6 |

| WC12 | 1 | 240 | 40 | 6 | 6 | 12 | 0.9 |

| WC21 | 2 | 240 | 25 | 6 | 6 | 12 | 0.6 |

| WC22 | 2 | 240 | 40 | 6 | 6 | 12 | 0.9 |

Burgos laminated 700 HB Wear-resistant Parts are the ideal solution for impact and high abrasion in the following industries:

- Earthmoving equipment and transhipment companies

- Cement plants

- Dredging industry

- Recycling industry

- Mineral processing industry

Burgos laminated 700 HB / 63 HRc Wear-resistant Parts benefits:

- Lower operating costs

- Longer Service when compared to conventional materials

- Increased production

- Improved product efficiency

- Increased equipment availability

Applications Burgos laminated 700 HB / 63 HRc Wear-resistant Parts:

- Chutes and liners

- Suction mouth dredging industry

- Protection of tunnelboring machines

- Shredder tips

- Protection dragheads dredging industry

- Protection earth moving equipment / shovels / buckets